Introduction

Designers of custom gears often face a critical dilemma in their work. The immediate response to heavy-load and wear-resistance requirements is usually to use the hardest steel possible. Unfortunately, this approach often meets with failure as the gears become brittle and prone to fracture under impact, generate too much noise, or are too costly to fabricate so that the service life is short. The main problem is that selection of material is oversimplified as just a “hardness race.” A truly scientific selection calls for a systematic framework that encompasses surface wear resistance, core toughness, manufacturability, and total cost of ownership-a holistic view that the traditional methods do not have.

The following article proposes a tactical framework, which is the result of twenty years of experience, combining gear working conditions, modes of failure, and material science in order to lead you to longer lifespan and lower total cost of ownership through smart gear material selection. First, we need to discard some common gear selection myths to achieve that.

Why is Selecting the Hardest Material Not the Answer for Long-Lasting Gears?

The pursuit of maximum hardness is a pervasive but flawed strategy. Understanding why requires a deeper look at material behavior and failure mechanisms.

1. The Misconception of “Harder is Always Better”

The biggest mistake would be to consider that a very high hardness level translates to optimum performance. Hardness always features in a high degree in wear resistance, yet in most cases, toughness, that is, resistance to impact and ability to deform without bursting, starts to decrease. A highly hardened gear often turns out to be like a glass object — it won’t get scratched easily, yet it will readily shatter when suddenly subjected to an impact, whereas in heavy machines and in car transmission, for example, impact performance is always a reality. The key point in any kind of trade-off between hardness or toughness has to be the starting point from which your choice begins.

2. How Excessive Hardness Can Accelerate Specific Failure Modes

Hardness is a vital characteristic of gear materials. But focusing solely on hardness can inadvertently accelerate other failure modes. For instance, an overly hard, brittle material is more susceptible to macroscopic pitting and spalling, where large chunks of material break away from the tooth surface under high contact stresses. Furthermore, the lack of toughness increases the risk of complete tooth breakage from shock loads, leading to catastrophic failure. In noise, sensitive applications, high, hardness materials can amplify gear whine (NVH, Noise, Vibration, and Harshness), making them unsuitable for precision robotics or consumer electronics.

3. The Critical Link Between Failure Mode and Material Property

The most significant mistake material engineers make is to start from a single property. This idea is well documented in the ASM Handbook chapter on gear failures. The correct selection process starts from the anticipated failure mode. Is the dominant issue abrasive wear from contaminated lubricants? Then high hardness is indeed key. Is it bending fatigue at the tooth root? Then high fatigue strength is paramount. Or is it impact loading? Then high toughness is non, negotiable. A material perfect for resisting wear may perform poorly under high cyclic bending stresses. A scientific approach matches the material’s properties to the specific mechanical and environmental challenges the gear will face.

What Constitutes a Scientific Framework for Gear Material Evaluation?

Moving beyond simple rules calls for a four, pillar framework to assess gear materials. Such a system guarantees that all the essential factors are taken into account together.

- Deconstructing the Load Spectrum and Environmental Demands: The first pillar is a thorough study of the gear’s operational reality. It is reckoned with the reality of the nominal torque and speed and it also considers load variations, the presence and the severity of shock loads, and the operating environment. Ambient temperature, lubrication type and condition, and exposure to corrosive elements or contaminants are some of the factors that can significantly affect the performance of a material. The gear that is functioning in a climate, controlled environment has different requirements than the one that is in dusty, high temperature mining application.

- Defining Clear Performance and Economic Objectives: Setting explicit targets is the second pillar. What is the required design life1, 000 hours or 10, 000 hours? What are the acceptable noise levels (NVH)? Are there weight restrictions? Most importantly, this pillar embraces Total Cost of Ownership (TCO), which not only accounts for the raw material cost but also the expenses caused by the machining difficulty, required heat treatments and the anticipated maintenance or replacement costs during the gear’s entire lifecycle.

- The Dynamic Interplay and Trade, Off Analysis: The framework is a dynamic interplay, not a checklist, where decisions in one area affect others. For instance, choosing a material for extreme weight reduction (e.g., titanium) will drastically increase direct costs but may be offset by fuel savings in aerospace. The core of precision engineering is trade, off navigation. The aim is to pinpoint the optimal point where performance requirements are achieved without excessive over, engineering, thus ensuring a genuinely cost, effective production outcome.

How Do Key Material Properties Directly Influence Gear Performance and Lifespan?

Understanding the specific role of key material properties is fundamental to making logical decisions within the evaluation framework.

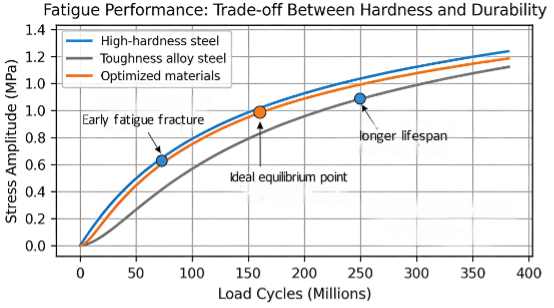

1. Fatigue Strength: The Key to Long, Term Durability

Fatigue is the primary cause of gear failures to be more than static overload. Fatigue strength defines how far a material can resist failure caused by repeated cycle of stresses, for instance, the bending stress of a tooth that is subject to each mesh. Based on the S, N curve principles from MIT Open Course Ware, the material with a high fatigue strength requirement can run a million times with the load, thus this property directly determines the gear’s lifespan. This characteristic is influenced by the alloy composition, purity (being free of inclusions), and, eventually, heat treatment.

2. Toughness and Core Hardness: The Defense Against Catastrophe

While surface hardness is what resists wear, the core of the gear tooth has to be tough and hard enough to support the hardened surface and withstand shock loads and bending stresses. A hard surface with a soft core can cause subsurface yielding and premature failure. Therefore, through, hardening is good for some applications, but case hardening (like carburizing) is generally better for high, stress gears, as it provides a hard, wear, resistant surface with a tough, ductile core that can absorb shocks.

3. Hardenability: Ensuring Consistency in Critical Sections

Hardenability is the ability of a material to develop a certain hardness level at a specific depth after quenching. It is very important for gears with larger tooth modules. A steel with low hardenability may only be hard on the very surface, while the core and root of the tooth will be soft and weak. High hardenability ensures that the mechanical properties set as the standard will also be there in the deepest sections of the gear tooth, thus performance remains consistent. This is one of the main differences between materials that look similar and are used for gear machining services.

How Can Advanced Gear Machining and Heat Treatment Synergize with Material Choice?

The inherent potential of the chosen material is only revealed when combined with advanced manufacturing and treatment processes. True performance is designed in the interplay between material and method.

1. Heat Treatment as a Performance Multiplier

Heat treatment should not be considered as merely the last step; it is actually an integral part of the material selection process. For instance, controlled atmosphere carburizing is a technique that can make a standard steel become a component of high performance with a superior case, core profile. In the same manner, precision induction hardening is a method by which specific areas such as the tooth flank can be locally hardened. The material selection has to be justified by the heat treatment processes’ capabilities and economics. To attain such accuracy and repeatability, it is frequently necessary to engage a partner who complies with stringent quality standards such as ISO 9001 and IATF 16949, which are indicative of high, professional gear machining services.

2. Precision Machining’s Role in Unlocking Material Potential

A great material can still be ruined by bad machining. To very close tooth geometry and to get a good surface finish of the gear that is the cause of low friction and thus efficient and smooth power transmission, advanced gear grinding and hobbing processes are absolutely necessary. Besides that, these modern manufacturing methods do not allow for any damage to the microstructure of the material during production so the full effect of the chosen alloy and heat treatment is delivered in the final part.

3. The Assurance of a Certified Quality Culture

One of the most certified quality systems such as AS9100D for aerospace is a sign of a manufacturer’s adherence to strict material traceability, thorough process controls, and rigorous durability testing. This quality culture acts as a guarantee that the complex interaction between material science and manufacturing technology is controlled with great discipline, which is extremely important for gears in high, reliability applications. This systemic approach is one of the core components of advanced industrial solutions.

Can You Provide a Case Study on Optimizing Gear Lifecycle Costs Through Material Science?

A real, life example makes it easier to grasp the efficiency of this strategic framework. A construction equipment manufacturer had a problem with the repeated failures of the drive gear in their excavators. Pitting failure was happening around 3, 000 service hours. The original material was standard 1045 steel.

- Analysis: The failure analysis, according to the framework, revealed that the surface hardness was sufficient for mild wear. However, the core strength and fatigue resistance were lacking for the high, impact, variable loads of excavation work.

- Solution: The material was changed to 4140 alloy steel. 4140 is more expensive per kilogram, but it has superior hardenability and toughness. The heat treatment protocol was made to produce a deeper, tougher case.

- Result: The new gears reached an extended service life of more than 8, 000 hours without failure. Even though the unit cost increased by about 15%, the total lifecycle cost was lowered by more than 40% because of the drastically reduced downtime and replacement part costs. This example demonstrates that choosing strategic, rather than simple, custom gears selection is a potent tool for value optimization.

What are the Practical Steps to Implement This Strategy in Your Next Gear Project?

Translating this framework into action requires a disciplined, collaborative approach.

1.Define the Mission Profile with Unprecedented Clarity

Start with a thorough duty cycle analysis. Don’t just average loads, but note peak loads, number of cycles, environmental conditions, and any other factors that could affect performance. This document becomes the base specification that material and process decisions are always compared to.

2. Engage in Early Collaboration for Design for Manufacturability (DFM)

Get your manufacturing partner on board during the design phase. An experienced partner can provide valuable DFM feedback about how different material choices will impact machining time, tool wear, heat treatment complexity, and overall cost. This early collaboration is often a great opportunity for discovering ways to simplify designs or choosing more easily manufacturable materials without performance loss, thus lowering project risk from the beginning.

3. Demand a Total Cost of Ownership (TCO) Analysis from Suppliers

Along with requests for quotes, have potential suppliers provide 2, 3 alternative material and process combinations along with a clear breakdown not only of piece, part cost but also of lead time, quality, and lifespan implications. A partner with good standing will be able to hold this discussion and show how their skill in custom gear design is a source of value beyond simple machining.

Conclusion

Choosing materials for high, performance gears used to be somewhat of a guessing game, but now it has become a scientific process. It requires that the people making the decisions move past just trying to make the gear as hard as possible, and instead use a strategic, systematic framework that combines material science, precision engineering, and a detailed knowledge of Total Cost of Ownership. Material selection then becomes one of the factors where you have to make a trade, off, but actually it is a very powerful instrument for extreme performance and a lasting competitive advantage.

FAQs

Q1: What is the most overlooked property when selecting materials for noise, sensitive gear applications?

A: Material damping capacity is frequently ignored. Apart from hardness, materials such as powdered metals have an intrinsic vibration absorption feature. If you only focus on hardness, you may end up increasing the noise of the gears.

Q2: How does material choice affect the overall cost of manufacturing a custom gear?

A: Material affects the cost not only through the direct expense but also through the machinability and the heat treatment requirements. A strategic choice of material balances the performance with manufacturing efficiency, thus leading to optimal cost, effectiveness.

Q3: For prototyping a new gear design, is it necessary to use the exact production, grade material?

A: Use production, grade material is a must for functional testing only. For form/fit checks, representative materials can be used. Work closely with your manufacturer to plan the material selection stages accordingly.

Q4: What assurances do international quality standards provide for gear material quality?

A: Material consistency is ensured by the ISO standards, and full traceability is also provided. Systematic quality controls are verified by manufacturer certifications, and material, related failures are avoided through rigorous verification processes that have been confirmed.

Q5: As a small business, how can we access material expertise without a large engineering team?

A: Consider your manufacturing partner as an engineering team member who is working outside your office. Get them involved early for DFM feedback so that you can benefit from their on, the, ground experience with similar projects, thus achieving the optimum both performance and cost.

Author Bio

The knowledge conveyed in this article is the result of the engineering team at LS Manufacturing, who aims at manufacturing high, precision custom gears and drive solutions. Their quality management system is certified according to ISO 9001, IATF 16949, and AS9100D. Get in touch with them if you need a consultation on how to optimize your gear design and material selection to get the best performance and value.