The Titan Powrliner 850 is widely recognized for its efficiency and durability in professional painting and coating projects. However, the performance and lifespan of this sprayer heavily depend on the quality and maintenance of its Titan Powrliner 850 parts. Understanding how each component functions can help professionals get the most out of their equipment.

1. Key Components That Influence Performance

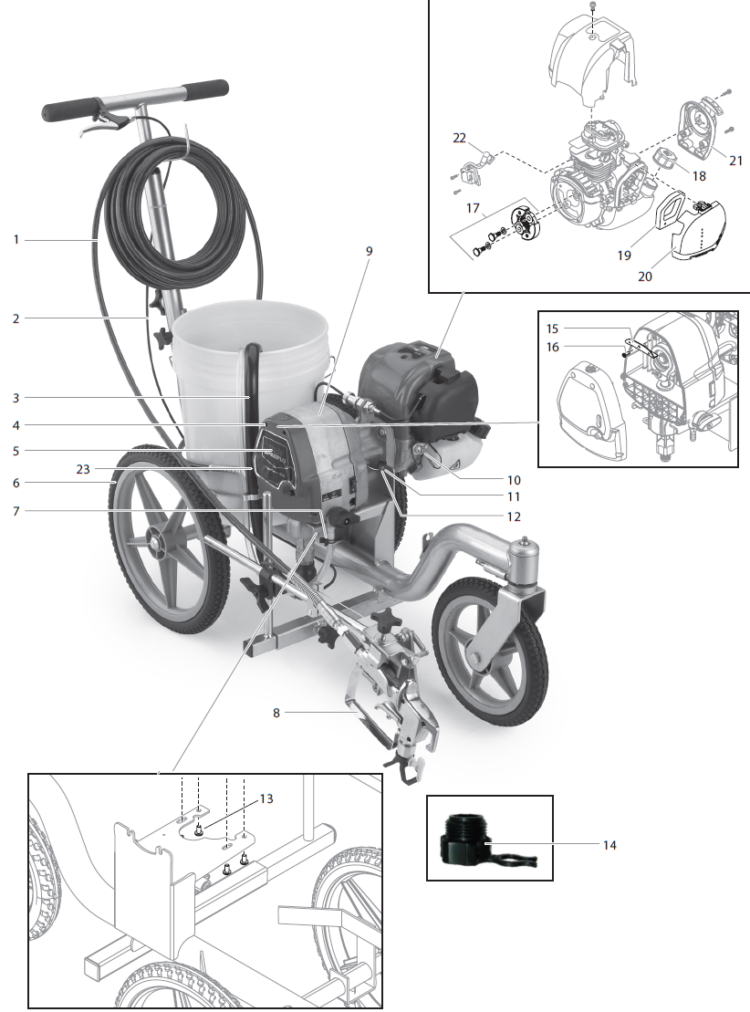

The sprayer’s performance relies on several critical components:

- Pump assembly: Responsible for consistent pressure, ensuring smooth and even application.

- Hose and fittings: High-quality hoses prevent leaks and maintain consistent flow.

- Spray tips and nozzles: The type and condition of the tip directly affect coverage and finish quality.

Regular inspection and timely replacement of worn-out Titan Powrliner 850 parts can prevent uneven spraying and equipment breakdown.

2. Importance of Maintenance

The sprayer achieves longer life through correct maintenance. Keeping the pump clean and moving components lubricated and worn parts replaced will maintain sprayer efficiency at its highest level. Maintenance neglect by professionals results in diminished spray pressure with uneven application that subsequently causes expensive repair work.

3. Longevity and Reliability

The sprayer will last longer when you use quality replacement components. Titan-built components handle industrial workloads more effectively which leads to fewer work stoppages and better system dependability. Users maintain their Titan Powrliner 850 unit’s steady performance by installing authentic replacement parts throughout long operation periods.

4. Cost-Effectiveness of Regular Replacement

The upfront cost of some components may look high initially yet immediate replacement of worn elements turns into a long-term cost saving procedure. The whole system maintains maximum efficiency when connected parts avoid early deterioration.

5. Tips for Optimal Use

- Always use manufacturer-recommended parts for replacements.

- Schedule regular maintenance checks.

- Keep the sprayer clean and lubricated to prevent corrosion.

Conclusion

Good care and the right parts are crucial to get excellent performance and durability from Titan Powrliner 850. The Professional-grade sprayer’s longevity and painting quality depend on maintenance and component knowledge coupled with timely replacement process. The initial investment in superior Titan Powrliner 850 replacement parts results in prolonged operational efficiency for these machines.