It isn’t easy to make clean and sturdy steel components. But there may be a procedure that makes it viable – it is referred to as casting. In casting, molten metallic is poured right into a unique mould. This mildew shapes the metallic and offers it its very last form.

The form is the most vital a part of this process. This determines how the element will appearance and how strong it’ll be. Let’s find out about mould tools in straightforward phrases.

What Is Die Cast Mold Tooling?

Casting tooling manner making the mold that shapes warm metallic into a product. You can consider it as a cake pan. When you pour cookie dough right into a mold, and it stays within the same form after baking. Likewise, after the molten metal has cooled, it takes the shape of the mildew.

The mould is made of very strong metallic as it should withstand excessive heat and stress. Each mildew is carefully designed to make sure that every product is ideal.

How Does Die Casting Work?

There are a few simple steps in the casting technique:

Melting a steel A metallic which includes aluminum or zinc is melted until it becomes liquid.

Filling the mildew The liquid metallic is pressed into the mould through intense pressure.

Cooling The mildew cools and the metal interior it solidifies.

Removing the part When the steel solidifies, the mold is opened and the completed part is removed.

Cleaning and completing The component is cleaned, and sharp edges are removed.

This entire system is speedy and may make loads of elements that each one appearance the equal.

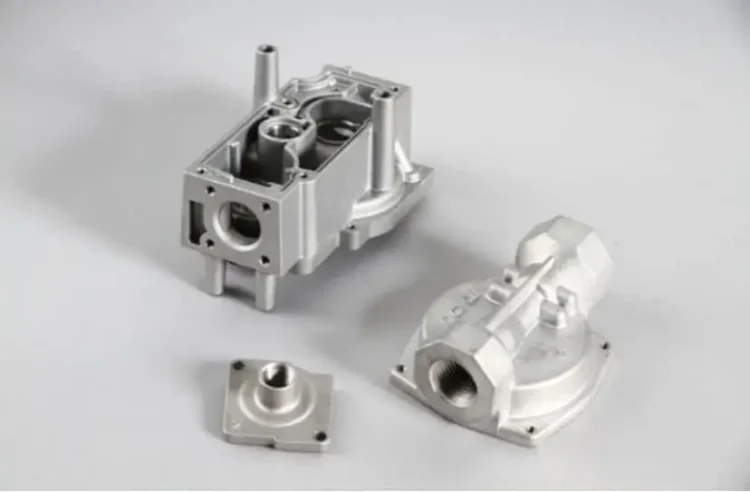

Main Parts of a Die Cast Mold

A cast mold has a few significant elements that help it feature:

Cavity and Core – These form the outer and internal edges of the component.

Ejector Pins – These help push the component out after it has cooled.

Cooling strains – These manage the temperature of the mould.

Runners and gate systems – These manual the liquid metal into the mold.

Valves – These launch trapped air.

Each component must be made cautiously so that the very last product is clean and smooth.

Types of Die Casting Molds

Different kinds of molds are utilized in casting:

Prototype mildew – used to test new designs before mass production.

Production forms – used for mass manufacturing.

Simple hollow space shape – make one part at a time.

Multi-hollow space mould – Makes several elements at the equal time.

The kind of mold depends to your product and how many pieces you need to make.

Benefits of Die Cast Mold Tooling

Die casting has many benefits. That’s why such a lot of industries use it nowadays.

Precise shape molds produce parts which are precisely fashioned and sized.

Smooth end, the part floor seems smooth and shiny with out extra polishing.

Rapid manufacturing: Once the mould is ready, and hundreds of components can be made quickly.

Such as Strong components Parts crafted from castings are strong and sturdy.

Less waste Almost all metals are used, so there’s very little waste.

Lower expenses for large orders When you’re making greater parts, the cost in step with piece is significantly reduced.

Creative layout You can without problems create exceptionally particular and complex shapes.

Materials Used in Die Casting

Many metals can be used in die casting. And The most common ones are:

- Aluminum – Light, does not rust, and strong.

- Zinc – Easy to mold and very durable.

- Magnesium – Very light and suitable for small parts.

- Copper – Robust and conducts heat well.

Each metal is chosen based on what kind of product is being made.

Why Mold Quality Is So Important

A good mold makes good products. If the mold has mistakes, the parts may come out rough or broken. That’s why professional die cast tooling services are so essential.

Experts design the mold using computer software. And They test it carefully before starting production. This helps save time and reduces waste. Like A well-made mold also lasts longer and gives better results.

How to Take Care of a Mold

Cast paperwork require care and cleansing to stay in proper condition. Here are some simple recommendations:

Clean the mould after each use.

Check for cracks or harm.

Use special coatings to shield it from heat.

Lubricate transferring elements regularly.

When well cared for, a mould can last heaps of production cycles.

Common Uses of Die Casting

Die casting is used in lots of industries because it gives desirable outcomes.

Automotive enterprise – for engine elements, wheels and gearboxes.

Electronics – for smartphone components, facts covers and chargers.

Aerospace – for aircraft and drone components that want to be mild and robust.

Household products – for handles, lovers and lighting fixtures parts.

Machines – for business device and frames.

Wherever metal elements are required, die casting is frequently the best preference.

Why Work with Professionals

If you need superb molds and ideal parts, it’s high-quality to paintings with specialists. Companies that offer solid tooling services recognize a way to design, check, and manufacture molds.

They assist store time, reduce expenses and make sure that each product meets excellent standards. A expert team uses cutting-edge machines and generation for the satisfactory effects.

If you want to work with experienced experts, then you can visit moldpartner.com. They provide advanced mold design and tooling solutions for all kinds of metal parts.

Final Thoughts

Cast die gear play a first-rate position in contemporary manufacturing. This enables to create merchandise which can be sturdy, clean and perfectly shaped. When completed effectively, it saves time, cash and materials.

Choosing expert die cast tooling offerings can make a significant difference in great and performance. They make sure that your molds closing a long time and that your merchandise look desirable.

To examine greater or start a brand new task, visit moldpartner.Com nowadays. You will get professional aid, present day system and the whole lot you want to make the nice metal merchandise in your commercial enterprise.