Introduction

Companies operating in the metal, cutting market must decisively overcome the prevailing production inefficiencies typical of 3-axis manufacturing processes. In addition, they need to figure out how to cut rising costs that inevitably follow such inefficient practices. Softly speaking, these are the tendencies of the current industrial market where 5-axis CNC machining has been the technology apparently rousing a lot of interest among all types of audiences.

As the article portends, the visitors renouncing shallow browsing are able to learn the practical insights into the strategic advantages of this sophisticated technology that is characterized by attaining a reduction in tolerance levels and costs dynamics. Keep reading to learn how it can be applied to your business and to see the future production landscape.

What is 5-axis CNC machining and how does it differ from traditional methods?

The Core Principles of 5-Axis Machining

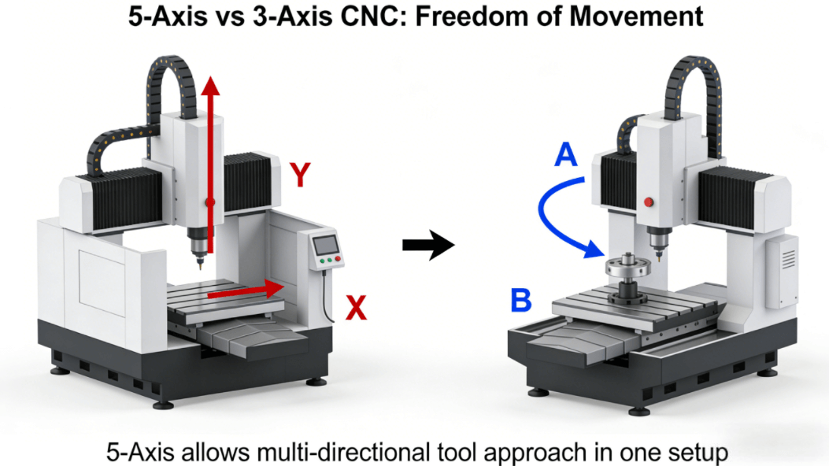

5-axis CNC machining is a major leap forward in the field of subtractive manufacturing technology. The National Aeronautics and Space Administration (NASA) Technical Standards System indicate whereas conventional 3-axis CNC machines are limited to three linear axes (X, Y, and Z), 5-axis machines add two more rotational axes (usually referred to as A and B). With this upgraded feature, the cutting tool can reach the workpiece from almost any angle in just one setup, thus the whole CNC machining process becomes much more fluid and continuous. industries that require component integrity and elaborate designs.

5-Axis vs. 3-Axis: A Comparison of Freedom and Precision

The fundamental difference between 5-axis vs 3-axis CNC machining is essentially the freedom of movement and the precision achieved as a result. Typically, a 3-axis machine needs to have the part set up several times in order to machine the different sides. On the other hand, a 5-axis machine moves the part and tool together along five axes, thus there is no need for multiple setups and all features of the part are naturally in the correct spatial relationships.

Practical Application: Reducing Setups and Enhancing Efficiency

The ability to single, setup machine is essentially transformative in terms of the practical benefits it brings. A component with a requirement to be worked on five faces would have to be subjected to at least three different setups on a 3-axis machine, while it can be done in just one on a 5-axis system . The overall production time is thus saved up to 30% or even more, errors related to changes in the fixture and handling by the operator are also significantly reduced simultaneously . Such efficiency, which is the basis of modern 5-axis CNC machining services turning to this technology for faster and more reliable parts, is very attractive to the customers. If anyone wants to achieve such efficiency, it is absolutely essential to take a step to find out about professional 5-axis CNC machining services.

What are the key benefits of using 5-axis CNC machining for industrial applications?

The use of 5-axis CNC technology opens up a wide range of revolutionary benefits of 5-axis CNC machining. It can attain the consolidation of many machining operations in one single setup, thus, it lessens the manual handling and the time needed for preparation. The efficiency achieved through this method halves labor costs and material waste, which is the reason for the double effect, a decrease in production time with CNC and the faster time, to, market, that it has on the whole production chain. The technology is, thus, a very promising and effective industrial manufacturing solution for high, value components.

A deep cavity, undercut or subtle contoured surface of a component is a typical example of a geometrically complex shape, and these types of components pose a significant challenge for 3-axis machines.The benefits also include better surface finishes, as the tool can follow contours more accurately with shorter and more consistent cuts, thus, secondary finishing operations are often eliminated. This highlights a key advantage of multi-axis machining.

How does 5-axis CNC machining ensure high tolerance and cost-effectiveness?

Achieving Exceptional Dimensional Accuracy

The National Institute of Standards and Technology (NIST) highlights advancements in precision measurement sciencethe 5-axis CNC machining tolerance possible on 5-axis CNC machining with this technology are incredibly fine, often within 0.005 mm or better. Such accuracy is achieved as a result of two main reasons: no multiple setups are involved, and shorter cutting tools can be used. When a part is machined in one clamping, all features are measured from a single datum, thus the assembly of tolerances which happens when the part is transferred from one fixture to another is eliminated. This firmness, which is very important in precision manufacturing, is one of the main reasons why the medical and aerospace industries, among others, use 5-axis machining for their essential components.

- The Role of Advanced Metrology

Achieving tight tolerances in a manufacturing process heavily depends on the use of advanced in, process probing and post, process inspection by means of Coordinate Measuring Machines (CMMs). These machines are used in verifying part dimensions against digital models thereby, allowing conformity to very strict specifications to be ensured.

- Importance of Supplier Certification

Choosing a supplier with internationally recognized quality certifications relevant to the industry (e. g. , ISO 9001, IATF 16949, AS9100D) is an important step towards quality consistency. A manufacturer like JS Precision that complies with such standards is an indication of their commitment to strong quality management systems which is a key requirement for industries that deal with high risks.

Analyzing the Cost-Effectiveness of 5-Axis Machining

When calculating the 5-axis CNC machining cost, one cannot simply focus on the machine’s hourly rate but has to take into account the total cost of ownership as well. Although the initial investment and programming complexity might be higher, the overall economics are favorable. Most of the cost savings come from reduced fixture costs, as fewer custom jigs are required. Labor costs are also reduced due to minimal manual setup and operation time. In addition, the high precision and quality lead to a decrease in scrap rates and thus the costs related to rework. Combining all these factors, 5-axis machining turns out to be a very cost, effective solution for complex parts, thus offering a substantial amount of value over the entire production lifecycle of the part.

- Reduced Scrap and Rework

High precision is the main reason for fewer rejected parts, which results in lower material waste as well as the costs related to correcting errors, thus improving the overall material yield and project economics.

- Faster Time-to-Market

The speed of single, setup machining is what mainly causes the short prototyping and production cycles and thus it is a significant competitive advantage. In the case of complex parts, the decision to take an experienced supplier offering 5-axis CNC machining is the best way to make sure these cost and time benefits are complete.

What industries benefit most from 5-axis CNC machining for complex parts?

The unique capabilities of a 5-axis machining system make it a technology that cannot be eliminated from sectors that require complex designs, are extremely precise, and can handle difficult materials. Complex parts 5-axis machining is most necessary in the aerospace industry. That industry needs light, strong components with complicated internal structures and complex surface curves, such as turbine blades and structural airframe elements . The ability to do this tooling on titanium solid blocks or high, temperature alloys with a minimum of set, ups is just what the industry standards for safety and performance are .The medical device industry, is the one to benefit most from the technology as well.

The need for custom, made surgical guides, prosthetic implants, and specialized surgical instruments requires a manufacturing process that can produce biocompatible parts with complex organic geometries and perfect surface finishes . 5-axis machining is a solution to applications of precision engineering which patient outcomes are critical.Other industries that abound in such technology are the automotive, energy, and defense . These industries are employing advanced manufacturing services to extend the limits of innovation, reliability, and component performance .

How to select the right 5-axis CNC machining service for custom projects?

Selecting a suitable partner for how to choose CNC services is absolutely essential to the success of a project involving complex parts. Initially, one should deeply analyze the technical capabilities and the demonstrated experience of the service provider with parts of similar size, complexity, and material as the project. Checking out their work and asking for case studies can give up a lot of information. Next, their quality assurance system should be a strong one. As it has been pointed out, very good reasons for trust in quality are the certifications like AS9100D for aerospace or ISO 13485 for medical devices. Do not hesitate to find out more about their inspection equipment and the steps they take to verify 5-axis CNC machining tolerance.

Effective support for custom part design is also very important. The best partner will provide detailed Design for Manufacturability (DFM) feedback, and will suggest changes that allow the part to be machined in a more efficient way, while still maintaining the same functionality. This teamwork is the main factor in cutting down production time with CNC and in being able to steer clear of expensive revisions by means of the iteration process. On top of that, check how they handle project management and communication.

A service provider that can be trusted will openly share information about lead times, pricing, and potential challenges, thus making the whole process from the quote to the delivery very smooth. By taking into account all these factors, companies will be able to find not only a partner that offers machining services but also one that makes an important contribution to engineering, therefore, ensuring the best outcomes for their custom projects.

Conclusion

In essence, 5-axis CNC machining represents a groundbreaking method of precise manufacturing that is able to achieve quicker production and greater accuracy of complicated parts. As a result of knowing the advantages and uses of 5-axis CNC machining, different sectors will be able to go beyond the restrictions of the past.

If you are the type of person who is looking for dependable solutions, then it would be a good idea to take a look at certified services so that you can be sure of getting the best results. Go to expert pages to discover more and make a request for a quote regarding your work.

Author Biography

This article was contributed by a manufacturing specialist at JS Precision, a company with AS9100D certification that helps aerospace and medical device engineers overcome complex machining challenges. check our free CNC Design for Manufacturability to optimize your next project.

FAQs

Q: What is the typical tolerance achievable with 5-axis CNC machining?

A: 5-axis CNC machining can achieve tolerances as tight as ±0.005mm, depending on the material and machine calibration. This high precision reduces the need for rework, making it ideal for industries like aerospace where accuracy is critical .

Q: How does 5-axis CNC machining reduce production costs?

A: By allowing complex parts to be completed in a single setup, it minimizes manual handling and setup time. This efficiency cuts labor costs and material waste, leading to overall savings of up to 30% compared to multi-step processes .

Q: What materials are suitable for 5-axis CNC machining?

A: Common materials include aluminum, titanium, and engineering plastics. The process handles hard metals well, ensuring durability for applications such as robotic arms or medical devices, with proper tooling selection .

Q: Can 5-axis machining be used for small-batch production?

A: Yes, it is highly flexible for both prototypes and small batches. The ability to quick-change designs without retooling makes it cost-effective for custom projects, supporting rapid iteration .

Q: What certifications should I look for in a 5-axis CNC service provider?

A: Key certifications include ISO 9001 for quality management and AS9100D for aerospace standards. These ensure adherence to international benchmarks, providing reliability for high-stakes industries.