Warehousing and logistics face constant pressure to move goods quickly while keeping expenses under control. Many operations struggle with rising labor costs, space limitations, and increasing customer expectations. A well-organized workflow creates stability, reduces waste, and strengthens performance across the supply chain.

Strong fundamentals, such as better layouts, upgraded tools, clear processes, and skilled teams, support consistent progress. The right combination of these elements helps a business stay competitive while protecting its margins.

Efficient Warehouse Layout Design

A well-planned layout shapes productivity more than most managers realize. Workers should move through the building without running into barriers, unnecessary detours, or crowded areas. Fast-moving products should be placed close to packing and shipping zones so teams can pick orders with less effort. Storage positions should follow a simple pattern that feels predictable and easy to memorize.

Clear labeling also supports smooth movement. Shelf tags, floor markings, and digital maps guide workers with minimal confusion. Good visibility allows teams to locate items quickly and handle orders with confidence. Slotting strategies help determine the best home for each product based on demand, size, and handling needs.

Smart Use of Material Handling Equipment

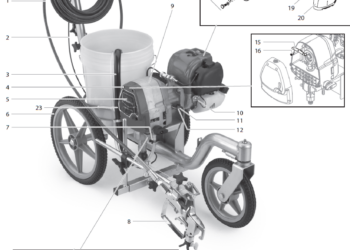

Material handling equipment influences the pace and safety of warehouse activity, so each tool should match the demands of daily tasks. When lifting capacity, maneuverability, and load requirements guide equipment selection, teams move goods with less strain and greater accuracy. Forklifts, pallet jacks, and lift trucks support different stages of handling, and their performance depends on strong components that keep them operating smoothly.

Routine checks and timely repairs reduce downtime and protect inventory from damage. Clear reporting also helps teams address mechanical issues before they disrupt operations. You can learn more about how the right forklift parts help boost efficiency and reduce costs in warehousing and logistics. This insight helps maintain long-term reliability and keeps the workflow steady during demanding periods.

Technology Adoption for Daily Operations

Warehouse technology improves clarity and reduces repetitive work. A warehouse management system organizes inventory data, tracks item locations, and updates records without relying on guesswork. Real-time visibility helps managers understand capacity limits, stock levels, and order status with greater precision. Barcode scanners and RFID tools support quick identification during receiving, picking, and packing. These tools shorten task times and lower error rates.

Automation also creates meaningful improvements. Conveyor systems, sorting machines, and automated storage units handle steady workloads without fatigue. Automated processes reduce the strain on workers and free them to focus on tasks that require problem-solving. Each tool contributes to a smoother workflow that supports long-term operational stability.

Strategic Inventory Management

Inventory control shapes costs more than many businesses expect. Forecasting demand helps managers plan purchase cycles with accuracy, which prevents overordering and stockouts. Cycle counting provides ongoing visibility so the team always knows what is available. This method catches discrepancies early and protects the business from expensive inventory surprises.

Storage strategies also influence efficiency. Products that sell quickly should remain in accessible positions. Slow-moving items should sit on higher racks or in less active zones. This arrangement shortens picking routes and keeps the warehouse organized.

Workforce Training and Skill Development

A well-trained workforce shapes the pace and quality of warehouse operations. Training sessions keep employees familiar with updated processes, new equipment, and safety expectations. Skilled workers complete tasks with fewer mistakes, which protects timelines and reduces rework. Regular coaching also builds confidence and encourages teams to take responsibility for their roles.

Strong safety programs protect both employees and equipment. Hazards decrease when teams understand how to lift correctly, operate machinery with care, and communicate clearly during busy periods. Productive operations grow naturally when workers feel supported and prepared.

Cost-Effective Transportation Planning

Transportation decisions influence both speed and overall spending. Careful planning helps the team avoid unnecessary miles, delays, and fuel use. Route planning tools identify the most practical paths for drivers based on distance, traffic patterns, and delivery schedules. These tools give managers the clarity needed to assign loads in a way that supports punctual deliveries and reduces stress on drivers.

Shipment consolidation strengthens savings as well. When compatible orders move together, the company spends less on fuel and vehicle wear. This approach also creates a more predictable flow for customers waiting for deliveries.

Data-Driven Decision Making

Data helps managers understand what slows the operation and what strengthens it. Key performance indicators reveal patterns in picking accuracy, travel time, labor hours, and inventory turnover. These indicators guide decisions that enhance productivity without guesswork. Regular reporting gives leaders a clear view of developing trends, which supports adjustments before small issues grow into major setbacks.

Trend analysis uncovers hidden cost leaks. Unusual spikes in damaged products, equipment downtime, or shipment errors signal the need for deeper review. Teams can refine workflows, adjust equipment usage, or update training plans based on this information. Steady use of data strengthens planning and creates a more consistent warehouse environment.

Continuous Improvement Culture

A culture of improvement brings new ideas forward and keeps the operation evolving. Employees who work on the floor often notice problems that managers may overlook. Encouraging feedback gives them a voice and helps the team uncover practical solutions. When feedback becomes part of the routine, the warehouse grows more adaptable and resilient during busy seasons.

Regular audits help identify outdated processes, slow routes, or clutter that disrupts productivity. These reviews highlight opportunities to adjust storage plans, reduce handling steps, or fine-tune equipment schedules. Small, clear goals guide steady improvement and prevent the process from feeling overwhelming. When progress becomes part of everyday thinking, the warehouse becomes more efficient and cost-effective over time.

Warehousing and logistics thrive when every part of the operation supports speed, accuracy, and stability. A strong layout, reliable equipment, smart technology, thoughtful inventory planning, and skilled teams work together to strengthen productivity.

Transportation planning, data insights, and continuous improvement reinforce these gains and protect the business from unnecessary costs. Consistent attention to these areas creates a warehouse that delivers dependable results while keeping expenses under control.