In every industrial and commercial electrical system, surge protection is critical from a safety planning perspective. Lightning strikes as well as internal switching activities can both cause power surges, which in turn can cause severe damage to equipment, halt production, and lead to long-term operational downtimes. These issues have made surge protective devices (SPDs) an integral component of modern electrical systems.

SPDs are often categorized into two types: Type 1 and Type 2. For engineers, facility managers, and procurement officers, knowing the differences between the two is of utmost importance. Having clarity on what each SPD type does and when to use it makes specifying protection strategies with electrical safety equipment suppliers much easier, leading to safer and more efficient systems.

Functions of a Surge Protective Device

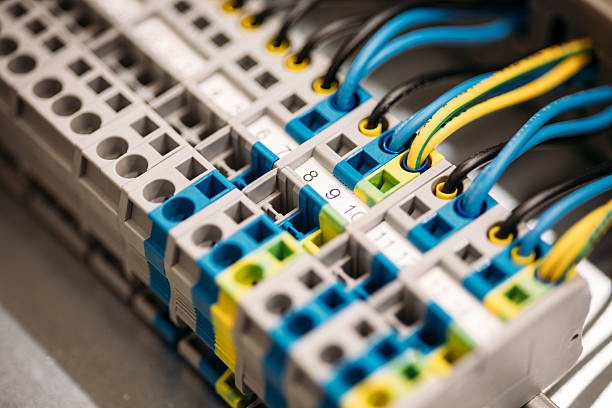

A surge protective device’s primary task is to limit transient overvoltages. SPDs can overvolt excessive voltage from the protected loads either by diverting it or clamping it. These overvoltages, or surges, can either result from external factors, such as lightning or from switching operations and equipment cycling.

The function of an SPD is to identify potential surge disturbances and re-route them safely to the ground to contain any critical surge energy. SPDs are designed differently to manage various kinds of surge events and their impacts.

This helps us define further the critical difference of SPDs Type 1 and Type 2 SPDs.

What is Type 1 SPD?

Service Type 1 SPDs are located typically on the service entrance of the facility either before or at the main distribution panel. Their main function is to safeguard the facility from external surges, such as lightning particles or other surges from the utility side.

This SPD is built to absorb energy from lightning particles or any other high-energy particles. In the case where the facility is equipped with external lightning protection systems (for instance, lightning rods), these systems are specialized to endure high energy surges. Type 1 SPDs are very tough and effective at draining high surge currents.

Buy or recommend a Type 1 SPD for buildings with overhead power lines designed for lightning strikes, those placed on the lower part of the hill or those containing critical instruments and infrastructures such as server farms, medical devices, and high-tech equipment.

What Is a Type 2 SPD?

Type 2 SPDs are positioned downstream of the main breaker, typically located within subpanels or distribution boards. Their main function is to mitigate residual surges that are likely to harm or exhaust delicate electronics, even if the surges are not powerful enough to trigger a Type 1 device.

These types of SPDs are required to protect modern facilities that are equipped with automated machines, data processing tools, and advanced communication equipment. Type 2 SPDs respond to the need for faster action and are tuned to cope with transient overvoltage interruptions created by internal operations, including motor start-ups and other self-inflicted chaos.

Typically, Type 2 SPDs are paired with Type 1 devices. This combination ensures that Type 1 manages the high-energy surges at the first point of contact and Type 2 processes the residual energy at the load centers.

SPD Type 1 vs Type 2: Key Differences in Application

Both Type 1 and Type 2 SPDs are designed to protect equipment from surges. However, their point of installation, evolution of energy capacity, and the configuration of their installation differs greatly between the two.

Type 1 SPDs are put in place to mitigate damages caused by external surges in hostile settings. Their use is appropriate in places with a lot of lightning activity and on the utility side of systems. Their operation is dependable, and they can withstand extreme surges. They are used before, or at the service panel, and are very resilient.

Type 2 SPDs are used further along the system hierarchy, protecting internal distribution systems and equipment from internal surges or those that have bypassed the Type 1 unit. They are critical in environments with high electrical activity because they are important for curbing damages to valuable equipment.

Surge exposure along with systems configuration with the connected equipment’s sensitivity influence the choice or combination of SPDs to use in the system. Such considerations are made with electrical safety equipment suppliers as reviews on SPD Type 1 and Type 2 are made.

Which One Do You Really Need for Your Facility?

The need for Type 1 and Type 2 SPDs is not one or the other; in most commercial and industrial setups, the need is for both.

As an example, if your manufacturing plant is located in an area with frequent thunderstorms, you would benefit from having a Type 1 SPD at the servicenter. This would intercept strong lightning strikes before reaching the plant’s internal electrical system. However, having this protection in place would not prevent PLCs, sensors, or computer networks from being damaged. For those cases, Type 2 SPD would be required.

A Type 2 SPD is typically used in urban environments, as there are reduced external surge threats. However, if there are internal switching transients, best practice would recommend having both installed as part of a full surge protection system.

In a single sentence, having trusted surge protection device providers enables organizations to operationalize their electrical surge safeguarding strategies precisely through the understanding of differences between SPD Type 1 vs Type 2.

Final Thoughts: Collaboration with electric safety equipment providers

Surge protection devices are not simply purchased and installed. If protection devices are not thoughtfully procured from trusted providers, an organization’s electrical safety, operational uptime, and mandated compliance layers are at risk.

Qualified vendors will assess your system setup to recommend the appropriate SPD types, assist with both local and international compliance considerations, as well as provide guidance for installation and ongoing maintenance to guarantee adherence to specifications. They are also able to project your future requirements, particularly if your plant is undergoing expansion or is planning to integrate renewable energy systems.

SPDs are vital components of every electrical system, so if you are installing a new system or upgrading an old one, it is important to know the function of every type and how they work collectively. Type 1 deals with the external, brute force surges. Type 2 deals with what Type 1 misses as well as internal noise. These two types of SPDs are critical to any comprehensive surge protection system.

Conclusion

In the context of surge protective devices, one cannot dispute the equal significance of Type 1 and Type 2 SPDs, and it is important to emphasize that both provide equal value and protection to critical infrastructure, operational continuity, and compliance with relevant mandates.

As you ponder on SPD Type 1 vs Type 2, view them as complementary and synergistic solutions for a single issue. One prevents surge strikes, the other mitigates damage to equipment. Working with good electrical safety equipment suppliers will help you to implement appropriate selection, installation, and maintenance strategies tailored to your facility’s risk profile.

In an environment where power quality is vital, and system outages are extremely costly, surge protection is no longer an optional feature, but a strategic investment.